If you are using a flange insert (flange liner or flange bushing) in an industrial setting and you suspect it might be too small, there are several signs you can look for to confirm your suspicion:

Difficulty Fitting Pipes: If the flange insert is too small, it may not fit the pipes or fittings properly. You might encounter challenges when trying to connect the flanges due to an inadequate bore size.

Leakage: A flange insert that is too small might not provide a secure and proper seal between the flanges. This can result in leaks at the connection point, leading to potential fluid or gas loss.

Increased Pressure Drop: Using an undersized flange insert can cause increased pressure drop across the connection, affecting the efficiency and performance of the fluid or gas flow.

Flange Damage: Forcing a flange insert that is too small into a larger flange bore can potentially damage both the flange insert and the flange itself.

Excessive Stress: An undersized flange insert may not be able to handle the load and stresses associated with the application, leading to premature wear and failure.

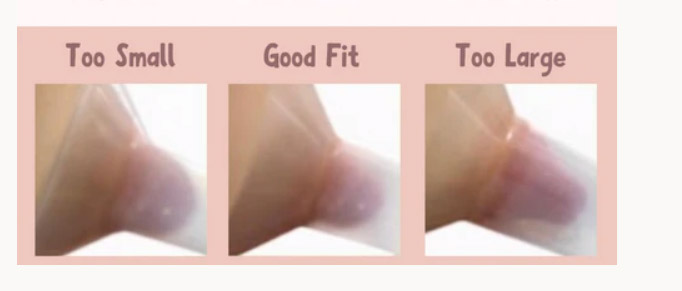

To determine if your flange insert is too small, it is essential to measure the inner diameter of the flange insert and compare it to the outer diameter of the pipe or fitting you intend to use. Additionally, always refer to the manufacturer's specifications and guidelines for proper flange insert sizing and installation.

If you are uncertain about the correct flange insert size or need assistance with selecting the appropriate components for your specific application, consult with a qualified engineer, or contact the manufacturer or supplier for expert advice. Ensuring the correct fit and functionality of flange inserts is crucial for maintaining a safe and efficient piping system.